Pro-3200-DB Routine Check Database Management Software

Overview

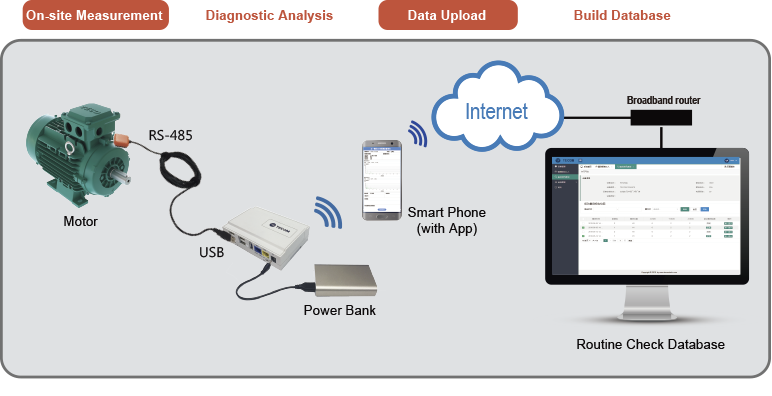

“Smart Portable Vibration Diagnosis Instrument” is a new generation of electromechanical equipment vibration measuring device. With this system, the Pro-3200 measurement data can be imported into the JSON format through the mobile APP or PC, providing information viewing, management and comparison of the electromechanical equipment, building a library for the factory equipment measurement and diagnostic data, and realizing the whole plant on the information management of the health status of electromechanical equipment is an effective tool for the traditional factory upgrade to industry 4.0.

Four Major Functions :

– Record the whole plant equipment status and information statistics.

– Instant import the Pro3200 measurement data diagnosis report by using remote mobil phone APP.

– Measurement and diagnostic data of electromechanical equipment, RMS, kurtosis, FFT spectrum comparison, historical

trend graph display

– Support equipment, report, system log and management functions

Features

1. Multi-language interface, suitable for users in different regions

2. Data support Json format

3. Report import mode supports PC local import and mobile APP remote import

4. Support single measurement, double stroke comparison and historical trend display of equipment measurement data.

5. Support data import and management of motors, compressors, pumps and other types of electromechanical equipment

6. Support system log query management.

Login to the home page and data import

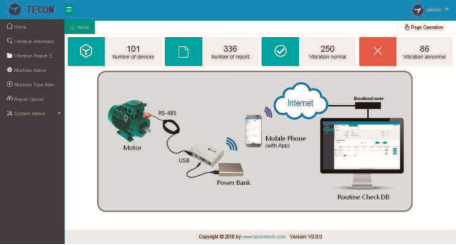

Visually display the entire factory inspection database, including the number of equipments, the number of reports, and the number of reports of normal and abnormal vibrations.

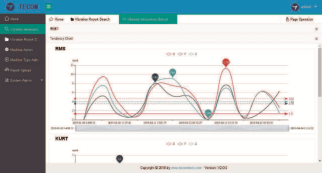

Report comparison

Different time data changes of the same measuring point of the equipment; RMS, kurtosis comparison; FFT comparison

Report presentation

- Basic equipment information and measurement time

- Vibration RMS, kurtosis, FFT and top-five energy

- Diagnostic results and maintenance recommendations

Historical trend display

The historical data trend of each parameter in the time interval of the same measuring point of the equipment, so that you can predict the time of equipment maintenance and quickly reach Industry 4.0

Configurations