Position

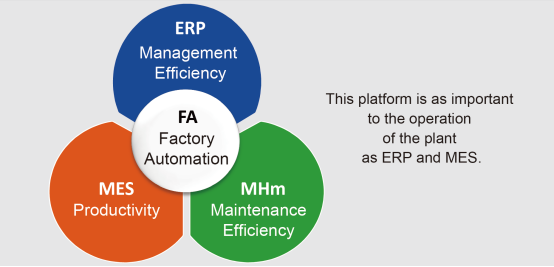

Factory automation has been in existence for many years, and the two main tools available are ERP and MES. However, there are other major assets in the factory, that is, mechanical and electrical equipment for production and service, which is not covered by existing ERP and MES.

The company's Smart Machine Health Management Platform (MHm) is aimed at the health management of the plant's electromechanical equipment, automating equipment maintenance and greatly improving the efficiency of factory maintenance.

Overview

TECO introduces the “All Smart Machine Health managing platform (MHm), an innovative and advanced solution for machine operation status management.

It uses MEMS (Micro Electrical Mechanical Sensor) sensors and the advanced-IoT (Internet of Things) communications technology to provide remote, mobile, real time, interactive functions between any machine and remote smart phones.

These functions are not possible for conventional SCADA systems or web-based on line monitoring systems. In a way, the MHm can be loosely considered as an advanced mobile SCADA.

In a factory…

There exist machines that are mission-critical and cannot afford to fail. These machines need constant monitoring and trending alerts. There are less critical machines but still need periodic health management to reduce unexpected shut down.

The TECO MHm platform comes with two product packages for the two different applications:

MMK/MHm Pro-3200

The Two Product Packages:

1. The MMK (Mobile Maintenance Kit), long-term monitoring:

The Kit is installed long-term on a machine, reports the machine operational status every second on 24-7 basis, using loT technology to work with remote smart phone, providing real-time monitoring, alarming, and interactive diagnosis.

2. Another product package is Pro-3200, on-site measurement:

-The Pro-3200 is a portable instrument for machine vibration measurements and diagnosis.

- It is used on routine measures of machine in a factory and can automatically save, file and establish Big-Data-capable Vibration data-base of all machines in the factory.

The two product packages are designed to complement each other.

The MMK is used for long-term health management of critical machines (maybe 10% in the factory) that cannot afford to fail.

For the rest of 90% machines, the Pro-3200 is used to do routine checks, save the measured data and establish vibration data-base of all machines in the factory. As the data-base is updated routinely, after a while the Big-Data algorithm will be able to give predictions on which machines are likely to fail, when and how.

Together with the MMK, the health of all machines in the factory are covered, at optimum cost.

MHm System Architecture Description

This architecture provides different designs for the factory and Setmaker

Designing MHm for the factory (near-end machine health management system)

Designing MHm-S (cloud machine health management system) for Set maker, providing Private Cloud/Public Cloud selection

MHM-S is mainly based on motor + air compressor, and will be extended to other industries the in future (example: water pump, ice water machine..)

Provides full range of vibration gauges: VB-200, VB-300, explosion-proof

Provide a comprehensive smart gateway:

AG-300, xDAQ-600 + high frequency piezoelectric vibration gauge

Provide VB-420SCB: 4~20mA analog vibration sensor, directly connected to the customer's current PLC/DCS system

Complete machine health management system solutions (Sensors - Gateway - MHm System -Cloud), covering high and low frequency vibration, temperature, pressure/flow, electrical energy and frequency converters... such as machine health parameter monitoring management.

Provides the interface between the gateway AG-300 and the customer's SCADA system.

, Fully in line with the Industrial Internet of Things IloT, you can receive real-time alarms, instant information, and analysis and diagnosis through the MMK APP on your mobile phone.

MHm System Component Description

Vibration measuring products :

VB-300ST : Industrial grade, stick-type, stainless steel, triaxial vibration gauge (with cable),RMS & FFT for speed & acceleration, displacement output, 316L stainless steel body, industrystandard RS-485, build-in cable (PVC).

VB-300SC : Industrial grade, screw lock-type, stainless steel, triaxial vibration gauge (with cable), RMS & FFT for speed & acceleration, displacement output, 316L stainless steel gauge,industry standard RS-485, built-in cable (PVC).

VB-300SCB : Industrial grade, screw lock-type, stainless steel, triaxial vibration gauge (sepa-ration cable), speed & acceleration RMS & FFT, displacement output, 316L stainless steelgauge, industry standard RS-485, separate cable.

VB-300SCT : Industrial grade, screw lock-type, stainless steel, triaxial vibration gauge (withTeflon cable), RMS & FFT for speed & acceleration, displacement output, 316L stainless steelgauge, industry standard RS-485, built-in cable (Teflon).

VB-420SCB : Industrial grade, screw lock-type, stainless steel, single-axis vibration gauge(separation cable), speed RMS output, 316L stainless steel gauge, industry standard 4~20mAsignal, separate cable.

VB-200ST : Industrial grade, stick-type, triaxial vibration gauge (with cable), speed & accelera-tion RMS, industry standard RS-485, built-in cable (PVC).

Temperature measurement products:

TS-200 : Adhesive temperature sensor, PT100Q, measuring temperature -15°C ~+ 150°C, measuring accuracy DINIEC 751 Class B. ± 1°C.

TS-300 : High-precision adhesive temperature sensor, PT100Ω, measuring temperature -30°C~150 °C, measuring accuracy DIN IEC 751 Class B. ± 0.5°C.

TM-100 : Magnetic temperature sensor, PT100Ω, measuring temperature -30°C~150 °C measuring accuracy Single DIN IEC 751 Class A.

Smart Gateway :

AG-300Plus : Mobile Maintenance Kit (MMK) Smart Gateway, RS-485, L AN/WAN/WiFi Support

Smart meter :

PM-300 : Smart multi-function three-phase meter, voltage 1 current l power 1 power l energy, RS-485 Modbus support.

Signal converter:

TT-300 : Temperature sensing signal converter, 3 ports of PT100 temperature signal input, 1 port of digital RS-485 signal output.

AD-300 : Analog-to-digital signal converter, 3 ports of 4-20mA and 1 port O-10V analog signal input, 1 port of digital RS-485 output.

Smart machine health management system platform