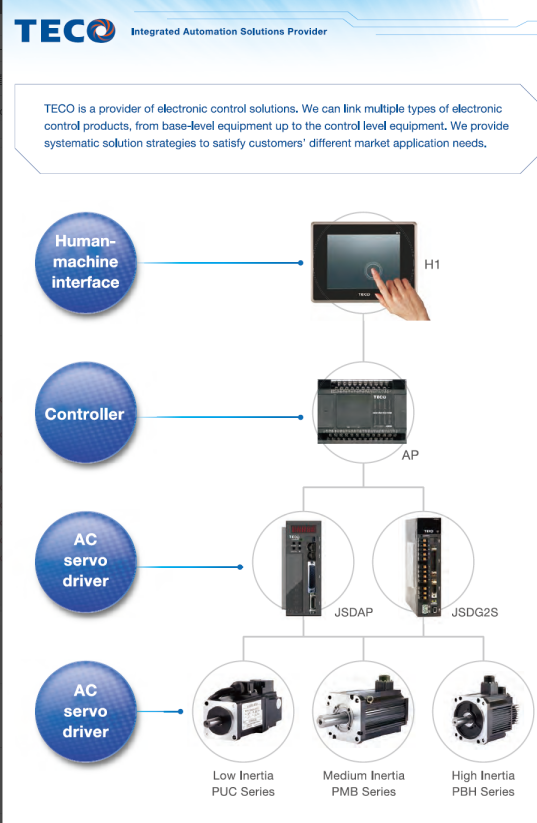

Integrated Automation Solutions Provider

TECO has long invested in the automation field. In the last 60 years, the company has continued to improve our automation knowledge from induction motors to different electronic control related products.

●Following the automation trend

TECO automation integration solutions for motors, drivers, and controllers matched with human-machine interface. TECO can provide different automation system solutions according to the customer's industry demands and applications. TECO professional electronic control skills and rich industry application experience can be used to continuously provide customers with high speed and precise automation products.

●Second generation- S

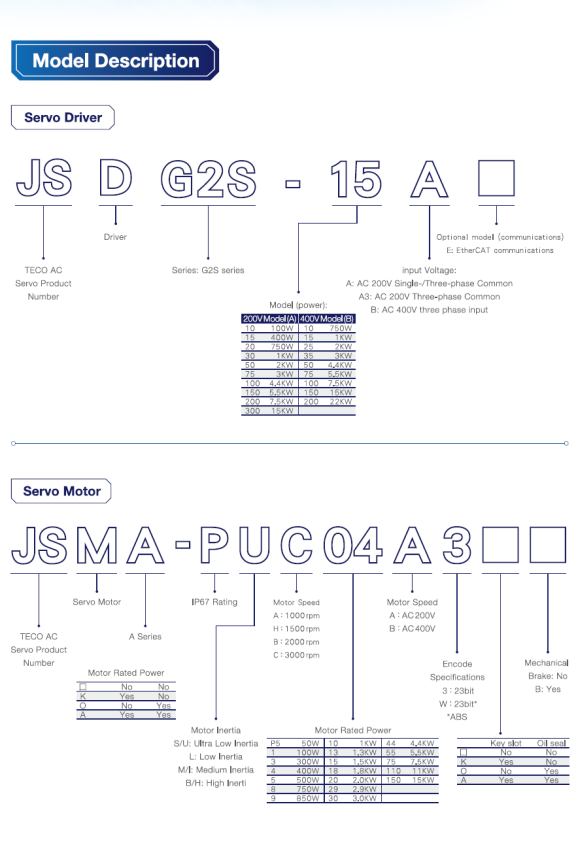

TECO is introducing the second generation servo product JSDG2S. G2 (Generation I) refers to brand new products produced using TECO'S market experience integrated with newly developed technology.

The “S” refers to servo characteristics brought to you by TECO. First, the brand new “slim” design clearly shows TECO's technological capabilities. "Stable” demonstrates that TECO servos are precise yet stable. “Suitable" states that TECO's brand new auto-tuning capability can be applied to different types of machines, and can make suitable adjustments.

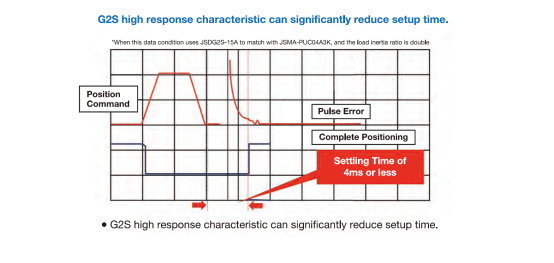

1.5 KHz High response bandwidth

1.8 times that of the previous generation

● Utilize high-end magnetic field control technology.

● Matched with high-speed computing core component.

● Shorten the arrival setting time.

● Improve the production capability of equipment and machines.

23 bit High-resolution encoder

10.000 times that of the previous generation

● 8,388,608 pulse/rev high resolution.

● Can be matched with incremental/absolute encoder.

● Provide machines and equipment with more precise positioning.

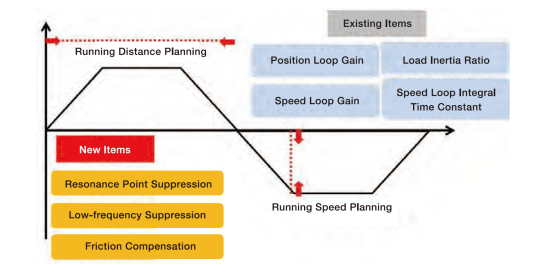

Automatically adjusts the gain

More detailed auto-tuning

In addition to the original normal gain parameters, G2S also has other added adjustment functions so that customers can make more precise adjustments for different applications and requirements. The simple PCLiNK interface can be used to complete setting and adjustments.

Resonance Suppression

◆Solved the resonance frequency of the machine mechanism so that it runs smoothly.

◆A total of eight high- and low-frequency resonance suppression points for multi-point setting according to machine requirements.